About our products

3

Product categories - developed from our own practice.

100%

Made with hand, heart and dedication.

1

Family workshop where it all begins

Your ollihess tool - a truly unique item

Whether mallet, friction mallet or gong - every ollihess product is unique and handmade. Each sound tool is the result of countless hours of experience with the gong, a great deal of patience, a keen sense of touch and the joy of craftsmanship.

The end result is a product that not only sounds unique, but is precisely tailored to your needs.

We make sound tools with character

The products created in our workshop are not off-the-shelf accessories: they are tools that make sound truly tangible. Each piece bears Olli's signature: thought through, implemented, tried out, adapted - until it not only feels right, but also opens doors to sound spaces you never knew existed.

Oliver Hess

"Sound is not created by chance. It begins with the care with which a tool is built."

Workshop with heart and family

What we create is real teamwork - in the best sense of the word. It's not just hands that work together in our workshop, but also generations.

Olli's son David lends a hand and takes care of shipping and organization, while Benni takes a look behind the scenes with his camera and editing.

Sound is a family affair for us - and that's what makes our products so special. We don't just produce here. Here we think, work and live together.

Handmade ollihess product categories

Professional Gong Mallets

Handmade mallets without annoying striking noise - for delicate nuances to deep vibrating rumble. Our mallets cover a wide sound spectrum.

Friction Mallets

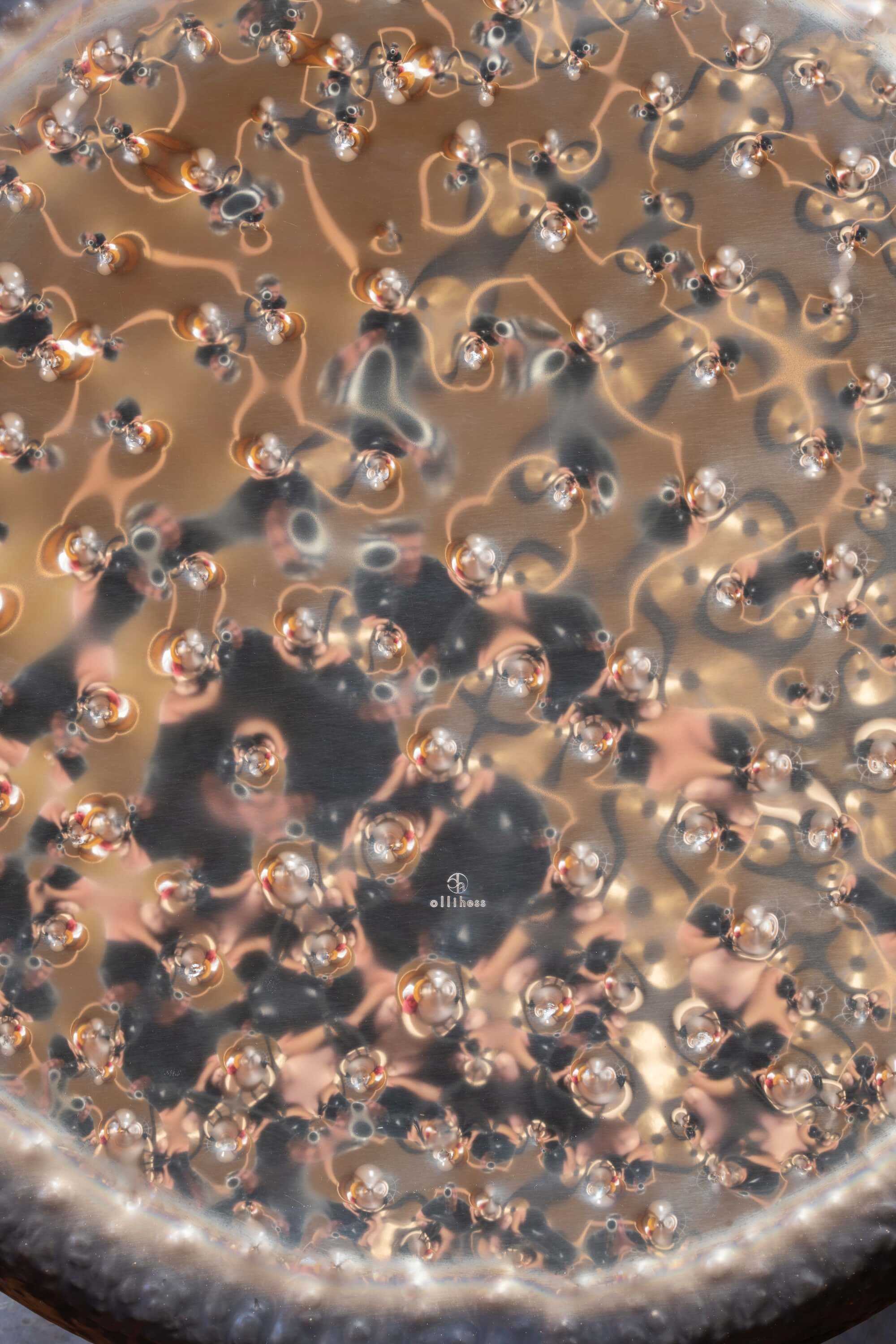

Our friction mallet open up a new cosmos of sound: spherical, floating, surprising - and designed and built entirely in our own workshop.

Gongs

Together with gong maker Broder Oetken, we develop nickel silver gongs - each piece is unique with its own sound character and the finest overtone structure

We combine craftsmanship with attitude

What we build should last a long time - for your sound and for the world we live in. Our materials and manufacturing processes are designed to handle resources with care, take responsibility and work with a good feeling:

- Regional raw materials such as beech, cork and natural caoutchouc - carefully selected and durable

- Recyclable packaging, reduced to the essentials

- Vegan product lines wherever possible - especially for mallets and graters

- Fair production in Germany, handmade and in close cooperation with family businesses

- Annual tree planting with Planet Tree - because the future needs more than words

The result is sound with attitude - conscious, honest and connected to what really matters.

Our materials

Beech wood

The wood we prefer to touch: regional, robust and fast-growing. Beech is just right for our handles - the ergonomically sanded wood feels good in the hand and has particularly good resonance properties.

natural caoutchouc

Light, elastic, durable - and completely biodegradable. natural caoutchouc brings warmth to the sound, balance to the playing and at the same time protects your sound instrument. For us, the perfect material for mallet and reamer heads.

Wellness fleece

Gentle on the gong, comfortable to play with: Our super-soft wellness fleece dampens background noise and keeps its shape even with frequent playing. It is easy to care for and available in many colors - perfect for clear sounds and your own style.

Cork

It comes from the bark, not from a felled tree - and has everything that is important to us: lightness, support, sustainability. A material that thinks for itself.

Nickel silver

Our sound metal. In collaboration with Broder Oetken, we make nickel silver gongs that can do more: vibrate softly, sound fine and last a long time.

Delve even deeper into our craft

What all products have in common: They are created from real practice, with a keen sense of material and form - and with the conviction that sound is only real if the tool is too. Here you can find out how an ollihess friction mallet is made.

In the workshop: A friction mallet is created

A look behind the scenes - from the first cut to the final finish.